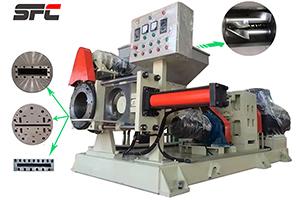

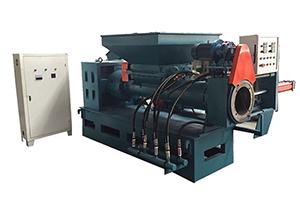

Rubber Strainer Machine

Request a Quote

Applications

Rubber strainer machines are used for multiple purposes in rubber processing. Besides removing impurities from rubber compounds, they can also be used to extrude the material into various profiles. Many rubber strainers setups combine both functions in a single rubber strainer to enhance processing and improve consistency.

This type of rubber processing equipment is commonly found in the manufacture of products such as EPDM sports flooring, inner tubes, and sealing strips. Because they use a forced-feed design, our rubber strainers can take rubber lumps straight from the kneader and process them automatically into continuous shapes, eliminating the need for manual feeding. In practice, the rubber strainer machines we offer can fully replace a mixing mill in this stage and reduce labor requirements by at least one operator.

Parameters

| Model |

XJL-150 |

| Screw diameter (mm) |

150 |

| Length/Diameter |

1:5.14 |

| Screw rotating speed (r/min) |

53 |

| Motor power (KW) |

37 |

| Vapor pressure (MPa) |

0.6-0.8 |

| Cooling water pressure (MPa) |

0.2 |

| Production capacity (㎏/h) |

450 |

| Weight (T) |

~4.5 |

| Model |

XJL-200 |

| Screw diameter (mm) |

200 |

| Length/Diameter |

4.5:1 |

| Screw rotating speed (r/min) |

45 |

| Motor power (KW) |

55 |

| Vapor pressure (MPa) |

0.6-0.8 |

| Cooling water pressure (MPa) |

0.2 |

| Production capacity (㎏/h) |

900 |

| Weight (T) |

~8 |

| Model |

XJL-250 |

| Screw diameter (mm) |

250 |

| Length/Diameter |

4:1 |

| Screw rotating speed (r/min) |

40 |

| Motor power (KW) |

110 |

| Vapor pressure (MPa) |

0.6-0.8 |

| Cooling water pressure (MPa) |

0.2 |

| Production capacity (㎏/h) |

1800 |

| Weight (T) |

~9 |

Description of Rubber Strainer Machine

- The strainer machine’s screw uses 38CrMoAIA materials that have undergone a tempering and surface nitriding treatment. The surface hardness is HRC60-65 and hard layer thickness is 0.4-0.6mm. The surface roughness is less than Ra0.8. Inside the screw, there is a pore path for temperature control circulating water, which serves for the heating and cooling of screw.

- The feeding cylinder is mainly composed of a rear body, front bushing and rear bushing. The structure is a jacketed cast iron.

The rear body is made of cast steel and contains a cavity where temperature control circulating water can flow through for the heating and cooling of the rear body.

The front & rear bushing uses 38CrMoAIA materials that have undergone a tempering and surface nitriding treatment.