EPDM Granules Production Line for Running Track

EPDM granules are widely used in running track, playgrounds, flooring and other applications. For the poured-in-place playground applications and outdoor running tracks, EPDM granules replace the traditional waste rubber, which avoids the health risks of users brought by excessive PAH production.

EPDM granules rubber features at non-toxic, safe, environmental protection and durable. Due to this, the demand for EPDM granules running track systems is booming.

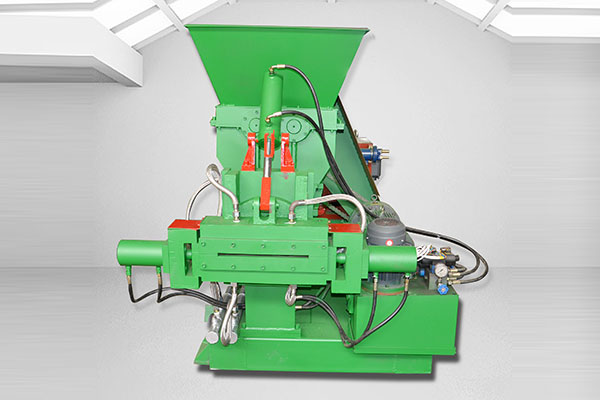

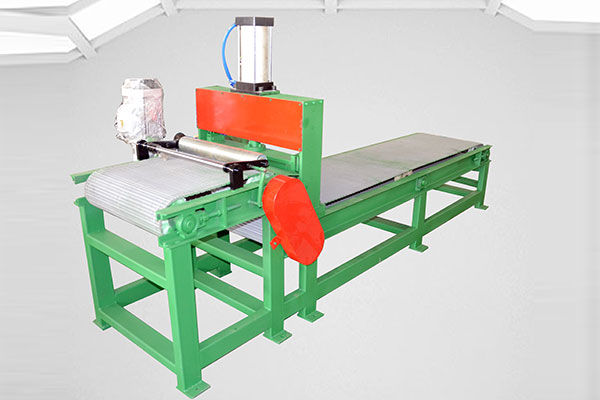

We provide EPDM granules production lines for track surface. Since 2015, we have been actively involved in the production of EPDM granules and have collaborated on projects with Qingdao University of Science and Technology.

So far, our company has provided numerous clients with EPDM granules production lines. In addition, we took part in the fabrication of EPDM granules (such as sulfur adding process, extruder head temperature control, etc.). Based on this, we continuously enhance the performance of our EPDM machinery. As a result, our equipment is among the best in China. Our EPDM manufacturing line, compared with the traditional line, our production line mainly has the advantages of fewer workers, high production efficiency and high degree of automation.

| Model | |||

| Screw diameter | 150mm | 200mm | 250mm |

| Screw L/D | 6.3 | 6 | 5.4 |

| Cylinder feeder length | 500mm | 600mm | 600mm |

| Screw maximum speed | 60r/min | 50r/min | 40r/min |

| Power of main motor | 45KW | 75KW | 110KW |

| Power of feeding motor | 5.5KW | 7.5KW | 7.5KW |

| Power of hydraulic motor | 3.7kw | 3.7kw | 3.7kw |

| Capability | 500-800Kg/h | 900-1500 Kg/h | 1500 -2000Kg/h |

| Steam pressure | 0.2--0.4MPa | ||

| Cooling water pressure | 0.2-0.4MPa | ||

| Overall dimensions | 3500×1650×1520 | 3700×1850×1750 | 4800×2150×1850 |