Products

Shun Cheong products feature a wide range of applications and our rubber kneading machines are no different. The kneading equipment is used to process various types of rubber products for manufacturing and recycling purposes. The high efficiency equipment is automated and allows for hassle free rubber handling.

Shung Cheong rubber mixing machines are extremely useful pieces of equipment that are designed to uniformly mix rubber components so that they can be optimally processed using additional equipment. These mixers are especially vital for the vulcanization process in which materials are pressed together to form highly uniform finished pieces.

Shun Cheong rubber vulcanizing presses are high quality pieces of machinery that can be counted on for consistent rubber vulcanization with outstanding results. The vulcanized rubber products produced using our presses can be counted on because of their durability and strength thanks to the high level of engineering that goes into the design of these machines.

Our rubber cooling machines are designed to cool and harden processed rubber products, usually at the end of the production process. The equipment is intended to expedite the final stages of production.

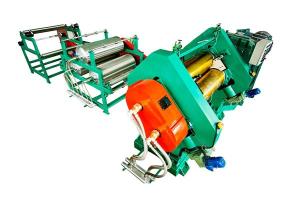

Shun Cheong rubber calendering machines are used to stretch and cut rubber materials into sheets so they can be processed using additional equipment. Calendering is an important process in the production of rubber products, particularly belts in which an inner fabric layer is used.

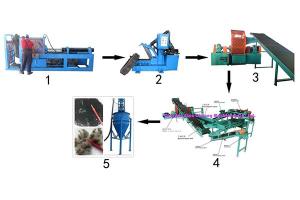

Tires are a product that used to take up huge amounts of space in landfills and were a noticeable waste of large amounts of usable materials. Today, we produce waste tire recycling lines to maximize the usefulness of materials and minimize waste.

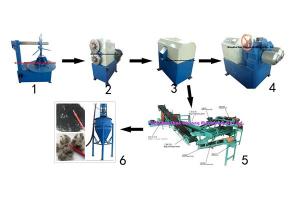

Reclaimed rubber is an ecologically friendly material that can be used to process new products without harvesting additional resources. Green production operations make use of reclaimed rubber production lines in order to minimize their ecological footprint and maximize their operating capabilities.

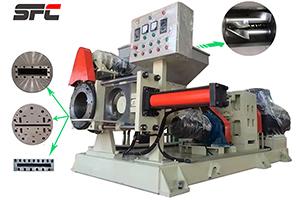

The goal of using a rubber extrusion machine is to get the highest amount of quality out of any given rubber product. Not all rubber materials are produced using a rubber extrusion machine, but those that are have gone through either a hot feed extruder or cold feed extruder. For added efficiency, the use of a co-extrusion line may be chosen as well depending on your application needs.

The EPDM rubber extrusion curing line is made up of products designed to extrude rubber materials in order to form the desired products in their intended shapes and structures. These machines are vital for the production of treaded tires, rubber hoses, inner tubes, cables, rubber threads, sealing elements, and a nearly unlimited number of other rubber products.

The conveyor belt vulcanizing press is designed for use in the production of rubber products, particularly rubber conveyor belts, automotive belts, sidewall belts, and steel wire conveyor belts.

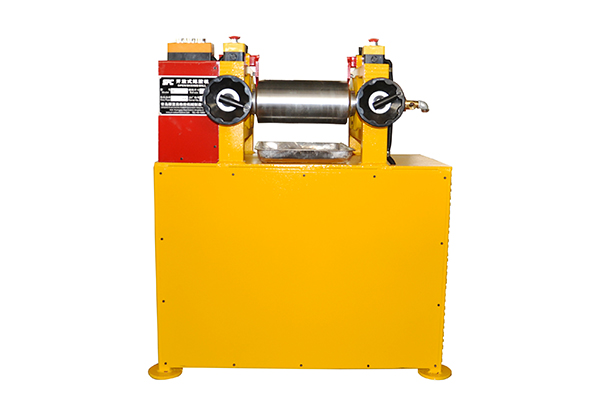

We offer a full range of high quality laboratory rubber machines that are both versatile and reliable, making them perfect for use in the processing of both common and special rubber compounds that are then used in a variety of applications.

As motorcycle tires and bicycle tires are smaller than traditional automobile tires, a specialized production line is needed for the manufacturing process.