Semi-Automatic Waste Tire Recycling Line

The semi-automatic waste tire recycling line is used for the recycling of various types of tires that are no longer suitable for use in their current state. By pulverizing waste tires to rubber particles or powders to prepare for further deep processing, the machine can produce rubber floor tiles, rubber mats, retread tires and produce a wide range of other rubber products.

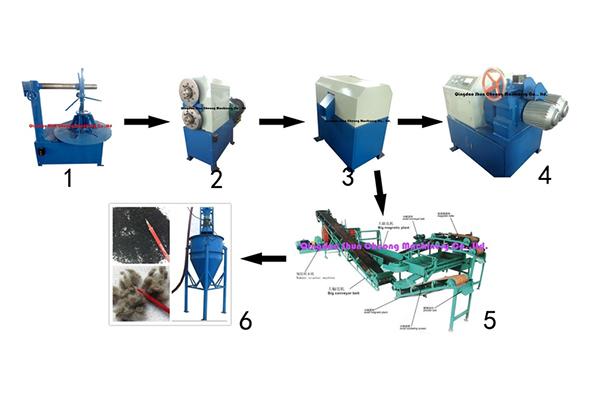

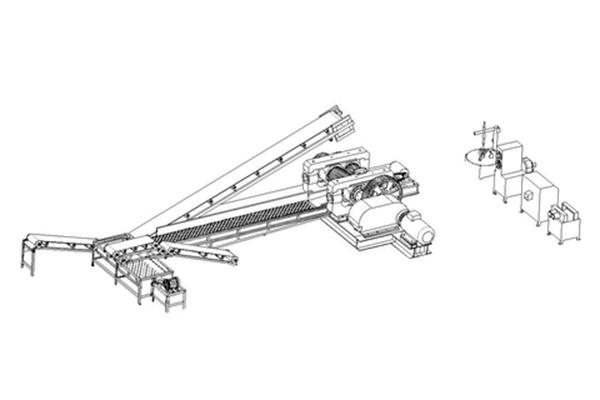

1. Use rubber ring cutter to separate sidewall and tread. → 2. Use rubber strip cutter to cut the separated sidewall and tread into 40-50mm wide stripes. → 3. Use rubber block cutter to cut the strips into 40-50mm rubber chunk. → 4. Use rubber cracker mill to crack the rubber chunks into rubber particles. → 5. Use rubber cracker mill auxiliary machines to screen out the needed particle size and separate steel wire. → 6. Use rubber fiber separator to separate the fiber from qualified rubber particles.

-

- Rubber Ring CutterMotor power (KW): 5.5

Main axle rotating speed (r/min): 46.8

Maximum diameter of tire (mm): 1200

-

- Rubber Strip CutterMotor power (KW): 5.5

Disc diameter (mm): 380

Main axle rotating speed (r/min): 18.4

-

- Rubber Block CutterMotor power (KW): 11

Main axle rotating speed (r/min): 420

Cutter outer diameter (mm): About 200

-

- Rubber Press Loop MachineMotor power (KW): 15

Front roller linear speed (r/min): 15.5

Speed ratio: 1.1

-

- Rubber Cracker MillThe rubber cracker mill can be used by waste tire recycling companies to crack rubber chunks into particles so as to...

-

- Rubber Cracker Mill Auxiliary MachineThe rubber cracker mill auxiliary machine is used by waste tire recycling operations.

-

- Rubber Fiber SeparatorPower: 5.5kw

Feed capacity: 1-2t/h

Dimension (mm): 1300*1300*4700

- The whole production line has the advantages of small floor area and easy operation.

- The power consumption is only 70% of traditional production lines.

- The vulnerable parts of the machine are mainly cutters and crusher rollers, all of which can be replaced and recycled.

- Due to small investment in semi-automatic waste tire recycling machine, this product is highly welcomed among Southeast Asian and Middle Asian clients. On average, we export over 5 production lines every year.

- We will send technicians to assemble, adjust each production line and train workers as well, so as to ensure optimal operation.