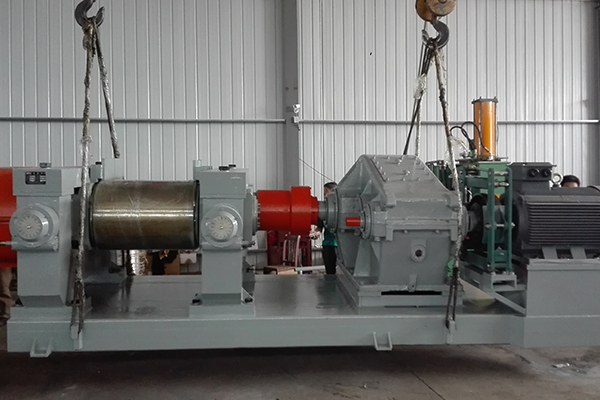

Rubber Cracker Mill

Applications

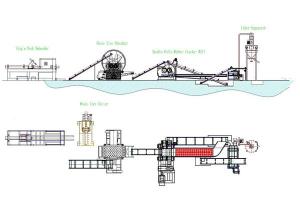

The rubber cracker mill is used by waste tire recycling companies to crack rubber chunks into rubber particles so as to separate the rubber from steel cords and other components embedded in the tire’s body.

Parameters

| Technical parameters | |

| Front roller diameter (mm) | 400 |

| Rear roller diameter (mm) | 400 |

| Roller length (mm) | 600 |

| Front roller linear speed (m/min) | 17.32 |

| Roller speed ratio | 1:1.38 |

| Motor power (kw) | 45 |

| Technical parameters | |

| Front roller diameter (mm) | 450 |

| Rear roller diameter (mm) | 450 |

| Roller length (mm) | 650 |

| Front roller linear speed (m/min) | 23.2 |

| Roller speed ratio | 1:1.38 |

| Motor power (kw) | 55 |

| Technical parameters | |

| Front roller diameter (mm) | 510 |

| Rear roller diameter (mm) | 560 |

| Roller length (mm) | 800 |

| Front roller linear speed (m/min) | 25.56 |

| Roller speed ratio | 1:1.30 |

| Motor power (kw) | 7590110132 |

| Technical parameters | |

| Front roller diameter (mm) | 560 |

| Rear roller diameter (mm) | 610 |

| Roller length (mm) | 8001000 |

| Front roller linear speed (m/min) | 32.2 |

| Roller speed ratio | 1:1.35 |

| Motor power (kw) | 132160 |

Product description

- We provide different types of rubber crackers according to production specifications.

- High accuracy, wear-resistance and low noise.

- Labyrinth seal, instead of oil seal, can avoid inconvenience of replacing framework oil seal while maintaining.

- The rack, gland and base of open mill all adopt welding structure. Surface quality is guaranteed.

- The adoption of an integrated base avoids severe vibration. In addition, such design does not necessarily need foundation. The machine can be moved freely on foundation surface.

- Electronic control cabinet is placed on the base which brings convenience for adjustment and installment. Once connected with dynamic power, cooling water and lubrication oil for reducer, the mill can start working.

- The rubber cracker’s roller has two types, cast steel roller and cast iron roller. The latter one is usually recommended, because it is more suitable for broken steel wire tire and convenient for welding and maintenance.

Get in Touch