Full-Automatic Waste Tire Recycling Line

The fully-automatic waste tire recycling line is used for the recycling of various types of tires that are no longer suitable for use in their current state. By pulverizing waste tires to rubber particles or powders to prepare for further deep processing, the machine can produce rubber floor tiles, rubber mats, retread tires and produce a wide range of other rubber products.

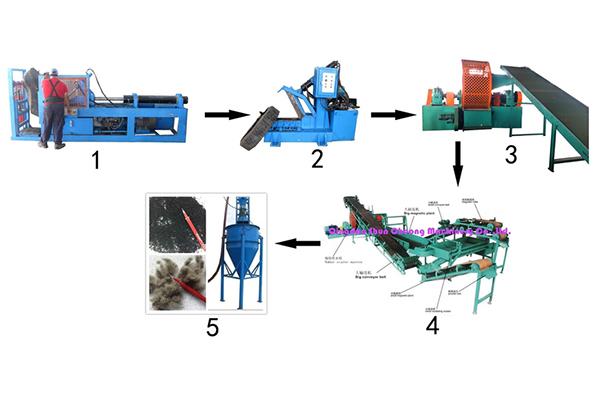

Use a bull block to separate the sidewall and tread. → Use tire cutter to cut the tire into big chunks. → Use whole tire crusher to crush tire chunks into 40-50mm tire chunks → Use rubber crusher to crush chunks into rubber particles. → Use rubber crusher auxiliary to screen out the needed particles and separate steel wires. →Use fiber separator to separate the qualified rubber particles from fiber.

-

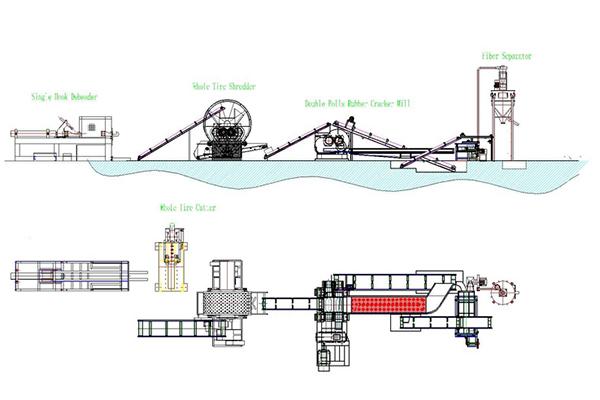

- Rubber Tyre DebeaderProduction capacity: 20-40 strips/hour

Motor power: 15 kw

Dimension (L×W×H): 4200*1200*1800 mm

-

- Rubber Tyre Cutter Production capacity: 20-50 strips/hour

Motor power: 11kw

Applicable tire diameter: ≤1500

-

- Whole Rubber Tyre ShredderDischarge dimension: 50*50mm

Waste rubber processing capacity: 2-3T/h

Motor power: 30kw*2

-

- Rubber Cracker MillElectronic control cabinet is placed on the base which brings convenience for adjustment and installment. Once connected with dynamic power...

-

- Rubber Cracker Mill Auxiliary MachineThe rubber cracker mill auxiliary machine is often used by waste tire recycling companies...

-

- Rubber Fiber SeparatorPower: 5.5kw

Feed capacity: 1-2t/h

Dimension (mm): 1300*1300*4700

- The whole production line can be easily operated by 2-3 workers.

- The vulnerable parts of the machine are mainly cutters and cracker rollers, all of which can be replaced and recycled.

- Features high automation with minimal reliance on manual labor, making the waste recycling process more efficient and freeing up resources for other tasks

- Main components, such as wear parts, are designed to be easy to repair, greatly extending their usable lifespan

- By utilizing energy-efficient motors and optimizing the roller speed ratios, our tire recycling line reduces energy consumption by approximately 15% compared to similar equipment, helping to lower operational costs while supporting sustainability goals

- We offer specialized post-processing equipment and technical expertise for rubber powder production, providing a comprehensive solution that helps businesses effectively reach the end market

- The fully-automatic waste tire recycling line has a long service life. Based on the working conditions, it usually can work for 2-3 years without any breakdown.

- We will send technicians to assemble, adjust each production line and train workers as well, so as to ensure optimal operation.