Three Roll Rubber Calendering Machine

Request a Quote

Applications

The three roll rubber calendering machine is a multifunctional piece of machinery designed for calendaring rubber sheet production, rubber sheet gluing, single-side gluing for fabric, and frictioning in rubber processing applications. The machine is widely applicable in the rubber product industry for the manufacturing of tires, cables, hoses, belts, and many other items.

Product parameters

| Model |

XY-3I 630 |

| Roller diameter |

mm |

230 |

| Working length |

mm |

630 |

| Roller speed ratio |

|

1:1:1 1:1.42:1 |

| Middle roller linear speed |

r/min |

0.8-8 |

| Adjusting range |

mm |

0-7 |

| Product minimum thickness |

mm |

0.2 |

| Product width |

Mm |

100-500 |

| Motor power |

kW |

7.5 |

| Dimension |

mm |

3168 |

| mm |

890 |

| mm |

1830 |

| Weight |

t |

~2.6 |

| Model |

XY-3I 900A |

| Roller diameter |

mm |

360 |

| Working length |

mm |

900 |

| Roller speed ratio |

|

1:1:1 0.733:1:1 0.733:1:0.733 |

| Middle roller linear speed |

r/min |

3-21.06 |

| Adjusting range |

mm |

0-10 |

| Product minimum thickness |

mm |

0.2 |

| Product width |

Mm |

500- |

| Motor power |

kW |

45 |

| Dimension |

mm |

5220 |

| mm |

1640 |

| mm |

2120 |

| Weight |

t |

~11 |

| Model |

XY-3I 1400 |

| Roller diameter |

mm |

400 |

| Working length |

mm |

1400 |

| Roller speed ratio |

|

1:1:1 1:1.383:1.383 1:1.383:1 |

| Middle roller linear speed |

r/min |

3-26.39 |

| Adjusting range |

mm |

0-10 |

| Product minimum thickness |

mm |

0.2 |

| Product width |

Mm |

1200 |

| Motor power |

kW |

55 |

| Dimension |

mm |

6500 |

| mm |

1500 |

| mm |

2440 |

| Weight |

t |

~22 |

| Model |

XY-3I 1500 |

| Roller diameter |

mm |

450 |

| Working length |

mm |

1500 |

| Roller speed ratio |

|

1:1:1 1:1.5:1 |

| Middle roller linear speed |

r/min |

2.62-26.2 |

| Adjusting range |

mm |

0-6 |

| Product minimum thickness |

mm |

0.2 |

| Product width |

Mm |

1400 |

| Motor power |

kW |

75 |

| Dimension |

mm |

7420 |

| mm |

2200 |

| mm |

2900 |

| Weight |

t |

~26 |

| Model |

XY-3I 1730 |

| Roller diameter |

mm |

610 |

| Working length |

mm |

1730 |

| Roller speed ratio |

|

1:1:1 1:1.4:1 |

| Middle roller linear speed |

r/min |

5.4-54 |

| Adjusting range |

mm |

0-20 |

| Product minimum thickness |

mm |

0.15 |

| Product width |

Mm |

1400 |

| Motor power |

kW |

132 |

| Dimension |

mm |

7010 |

| mm |

3950 |

| mm |

3730 |

| Weight |

t |

~52 |

| Model |

XY-3I 2130 |

| Roller diameter |

mm |

710 |

| Working length |

mm |

2130 |

| Roller speed ratio |

|

1:1:1 |

| Middle roller linear speed |

r/min |

8-50 |

| Adjusting range |

mm |

0-20 |

| Product minimum thickness |

mm |

0.15 |

| Product width |

Mm |

1900 |

| Motor power |

kW |

185 |

| Dimension |

mm |

7650 |

| mm |

4560 |

| mm |

4080 |

| Weight |

t |

~67 |

| Model |

XY-3I 2430 |

| Roller diameter |

mm |

810 |

| Working length |

mm |

2430 |

| Roller speed ratio |

|

1:1:1 1:1.5:1 |

| Middle roller linear speed |

r/min |

2-20 |

| Adjusting range |

mm |

0.5-25 |

| Product minimum thickness |

mm |

0.5 |

| Product width |

Mm |

2150 |

| Motor power |

kW |

220 |

| Dimension |

mm |

9300 |

| mm |

3150 |

| mm |

5200 |

| Weight |

t |

~94 |

Product description of Three Roll Rubber Calendering Machine

- Three roll rubber calendering machine is equipped with Swedish SKF bearings to guarantee calendering accuracy.

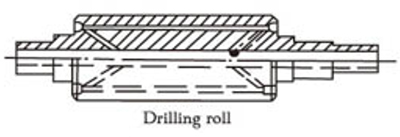

- Roller utilizes a rolling bearing to reduce friction and save energy. Labyrinth seal with thin oil lubrication to prevent oil leakage.

- The integrated base prevents severe vibration. In addition, such a design does not necessarily need foundation. The machine can be moved freely on a flat surface.

- Electronic control cabinet is placed on the base which provides convenience for adjustment and installation. Once connected with dynamic power, cooling water and lubrication oil for the reducer, the mill can begin operation.

- The calendering precision reaches ±0.02mm, ensuring that the roller height consistently meets the calendering requirements, which guarantees uniform thickness and quality in the final rubber products

The peripheral drilling design of the rollers enhances cooling efficiency, keeping the rubber at an optimal temperature during the calendering process

The automatic lubrication system ensures consistent and timely oil delivery, reducing wear and tear on critical components

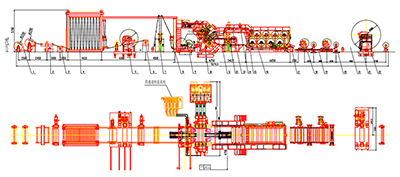

We offer customized rubber feeding systems, as well as auxiliary equipment for both pre- and post-calendering stages, tailored to meet the specific needs of our clients' production lines

Our advantages

- Shun Cheong considers the end user from each process of production from design, manufacturing and maintenance of the three roll rubber calendering machine. For example, the assembly and installation of the three roll calendering machine usually takes 6 days and 7 processes, while the new one takes only 3 hours and 4 processes.

- Shun Cheong manufactures about 40 pieces of different types of rubber calender machines every year and we provide custom services to meet client demands.