Cold Feed Rubber Extruder Machine

Applications

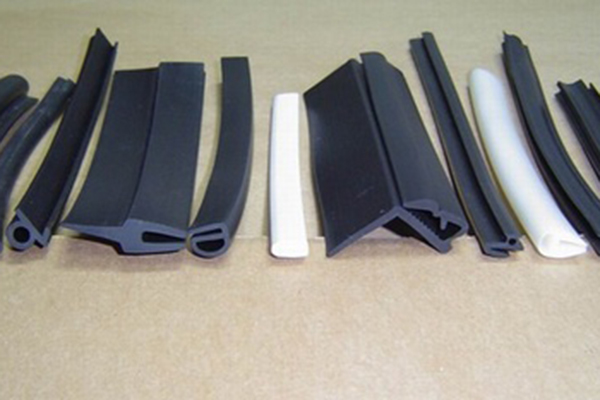

The cold feed rubber extruder machine is designed and manufactured for the extrusion of rubber materials used in the production of treaded tires, rubber hoses, inner tubes, cables, and a wide range of other rubber products. The cold feed extrusion process is highly energy efficient and provides added safety during operation compared to hot fed equipment.

Parameters

| Technical Parameters | |

| Screw Diameter(mm) | 75 |

| L : D | 20:1 |

| Screw Rotating Speed (r/min) | 5-65 |

| Max. Extruding Capacity (kg/h) | 120 |

| Main Motor Power(kw) | 37 |

| Speed Adjustment Mode | Frequency variable speed control |

| Weight (kg) | 1700 |

| Technical Parameters | |

| Screw Diameter(mm) | 90 |

| L : D | 20:1 |

| Screw Rotate Speed (r/min) | 5-55 |

| Max. Extruding Capacity (kg/h) | 320 |

| Main Motor Power(kw) | 55 |

| Speed Adjustment Mode | ariablefrequency speed regulation |

| Weight (kg) | 3200 |

| Technical Parameters | |

| Screw Diameter(mm) | 120 |

| L : D | 20:1 |

| Screw Rotate Speed (r/min) | 5-55 |

| Max. Extruding Capacity (kg/h) | 600 |

| Main Motor Power(kw) | 110 |

| Speed Adjustment Mode | ariablefrequency speed regulation |

| Weight (kg) | 5200 |

| Technical Parameters | |

| Screw Diameter(mm) | 150 |

| L : D | 20:1 |

| Screw Rotate Speed (r/min) | 5-55 |

| Max. Extruding Capacity (kg/h) | 800 |

| Main Motor Power(kw) | 150 |

| Speed Adjustment Mode | a ariablefrequency speed regulation |

| Weight (kg) | 6500 |

Get in Touch