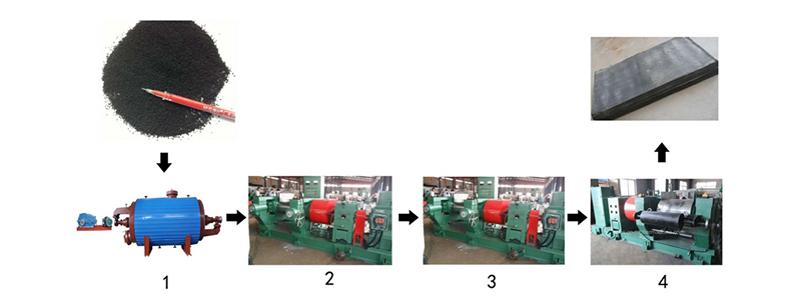

Rubber Refining Mill

Applications

The rubber refining mill is used to refine reclaimed rubber materials in order to produce brand new rubber products. It works by mixing thin rubber sheets to make new, thicker rubber sheets.

Parameters

| Technical parameters Model | ||

| Front roller diameter (mm) | 450 | 480 |

| Rear roller diameter (mm) | 510 | 612 |

| Roller length (mm) | 8001000 | 8001016 |

| Front roller linear speed (m/min) | 48/32 | 22.97 |

| Front and rear roller speed ratio | 1:1.27 | 1:1.82 |

| Maximum roller spacing (mm) | 10 | 15 |

| Motor power (kw) | 55 | 7590 |

Product description of the Rubber Refining Mill

- The friction gear of the reclaimed rubber refining mill lies between the roller and reducer, so as to prevent the cooling water from mixing with the lubrication oil trough.

- The hardened reducer is grinded and treated by carburizing quenching techinques, which increases accuracy, wear-resistance and lowers noise output.

- Adoption of rolling bearings helps to reduce the friction. A labyrinth seal, instead of an oil seal, can avoid the inconvenience of replacing framework oil seals while maintaining.

- The rack, gland and base of the open mill adopt a welded structure. Surface quality is guaranteed.

- The adoption of an integrated base prevents severe vibration. In addition, such designs do not necessarily need foundation. The machine can be moved freely on any foundation surface.

- The machine is equipped with a scram button and kick switch for added safety.

- We adopt the latest national safety standards 'GB20055-2006 Open Mill Safety Standards’, which are generally the same as European CE Standards. The braking length of the roller can be 1/6 rotation for safety.

- Electronic control cabinet is placed on the base which provides precision for adjustment and installation. Once connected with dynamic power, cooling water and lubrication oil for reducer, the mill can start working.

Get in Touch