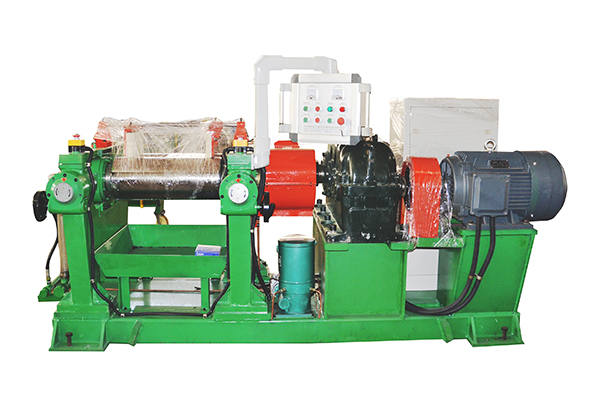

Rubber Mixing Mill

Applications

The rubber mixing mill produced by Shun Cheong is specially engineered for the milling process of rubber and rubber products. You will find rubber mixing mills in factories used to produce tires, cables, rubber hoses, belts, and many other rubber products. The mixers are dynamic, however, and they can be used to mix other products such as oil paint, dyes, ceramics, medicines, and many more.

Product parameters

| Technical parameters model | |

| Roller diameters(mm) | 160 |

| Roller length (mm) | 320 |

| Front roller linear velocity (m/min) |

8.95 |

| Roller velocity ratio | 1:1.35 |

| Maximum roller spacing (mm) | 4.5 |

| Capacity per batch (kg) | 1-2 |

| Motor power (kw) | 5.5 |

| Dimension: L×W×H(mm) |

1380×860 ×1320 |

| Technical parameters model | |

| Roller diameters(mm) | 230 |

| Roller length (mm) | 600 |

| Front roller linear velocity (m/min) |

10.21 |

| Roller velocity ratio | 1:1.19 |

| Maximum roller spacing (mm) | 7 |

| Capacity per batch (kg) | 6-10 |

| Motor power (kw) | 15 |

| Dimension: L×W×H(mm) |

2800×1200 ×1120 |

| Technical parameters model | |

| Roller diameters(mm) | 250 |

| Roller length (mm) | 620 |

| Front roller linear velocity (m/min) |

14.1 |

| Roller velocity ratio | 1:1.17 |

| Maximum roller spacing (mm) | 8 |

| Capacity per batch (kg) | 8~15 |

| Motor power (kw) | 18.5 |

| Dimension: L×W×H(mm) |

3400×1500 ×1650 |

| Technical parameters model | |

| Roller diameters(mm) | 300 |

| Roller length (mm) | 750 |

| Front roller linear velocity (m/min) |

15.1 |

| Roller velocity ratio | 1:1.25 |

| Maximum roller spacing (mm) | 10 |

| Capacity per batch (kg) | 15~20 |

| Motor power (kw) | 22 |

| Dimension: L×W×H(mm) |

3500×1600 ×1700 |

| Technical parameters model | |

| Roller diameters(mm) | 360 |

| Roller length (mm) | 900 |

| Front roller linear velocity (m/min) |

16.25 |

| Roller velocity ratio | 1:1.25 |

| Maximum roller spacing (mm) | 10 |

| Capacity per batch (kg) | 20~25 |

| Motor power (kw) | 30 |

| Dimension: L×W×H(mm) |

3780×1850 ×1750 |

| Technical parameters model | |

| Roller diameters(mm) | 400 |

| Roller length (mm) | 1000 |

| Front roller linear velocity (m/min) |

18.65 |

| Roller velocity ratio | 1:1.27 |

| Maximum roller spacing (mm) | 10 |

| Capacity per batch (kg) | 18-35 |

| Motor power (kw) | 37 |

| Dimension: L×W×H(mm) |

4350×1850 ×1785 |

| Technical parameters model | |

| Roller diameters(mm) | 450 |

| Roller length (mm) | 1200 |

| Front roller linear velocity (m/min) |

24.26 |

| Roller velocity ratio | 1:1.27 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 25-50 |

| Motor power (kw) | 55 |

| Dimension: L×W×H(mm) |

5200×2380 ×1840 |

| Technical parameters model | |

| Roller diameters(mm) | 560/510 |

| Roller length (mm) | 1530 |

| Front roller linear velocity (m/min) |

27.72 |

| Roller velocity ratio | 1:1.2 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 35~50 |

| Motor power (kw) | 90 |

| Dimension: L×W×H(mm) |

5845×2284 ×1978 |

| Technical parameters model | |

| Roller diameters(mm) | 550 |

| Roller length (mm) | 1500 |

| Front roller linear velocity (m/min) |

27.94 |

| Roller velocity ratio | 1:1.22 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 50~60 |

| Motor power (kw) | 110 |

| Dimension: L×W×H(mm) |

5870×2475 ×2045 |

| Technical parameters model | |

| Roller diameters(mm) | 610 |

| Roller length (mm) | 2000 |

| Front roller linear velocity (m/min) |

28.42 |

| Roller velocity ratio | 1:1.17 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 120-150 |

| Motor power (kw) | 160 |

| Dimension: L×W×H(mm) |

7070×2290 ×1840 |

| Technical parameters model | |

| Roller diameters(mm) | 660 |

| Roller length (mm) | 2130 |

| Front roller linear velocity (m/min) |

28.6 |

| Roller velocity ratio | 1:1.24 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 210 |

| Motor power (kw) | 245 |

| Dimension: L×W×H(mm) |

7465×3662 ×2080 |

| Technical parameters model | |

| Roller diameters(mm) | 710 |

| Roller length (mm) | 2200 |

| Front roller linear velocity (m/min) |

30 |

| Roller velocity ratio | 1:1.09 |

| Maximum roller spacing (mm) | 15 |

| Capacity per batch (kg) | 280-300 |

| Motor power (kw) | 280 |

| Dimension: L×W×H(mm) |

7500×3500×1800 |

Product description

- The friction gears of the rubber mixing mill sit between the roller and reducer to avoid cooling water and condensate water from entering into lubricating oil trough.

- The rubber blending mixing mill features a hardened gear reducer. Gears are all treated using carburizing and quenching techniques. Each gear surface is carefully grinded as well. Such processes provide higher machining accuracy, higher wear-resistance, and lower noise.

- Adoption of a rolling bearing for the roller helps to minimize friction. A labyrinth seal, instead of an oil seal is used to prevent the inconvenience of replacing the framework oil seal while maintaining.

- The rack, gland and base of the open mill feature a welded structure.

- The adoption of an integrated base prevents severe vibration. In addition, such design does not necessarily need foundation. The machine can be moved freely on the foundation surface.

- The rubber mixing mill is equipped with a scram button and foot switch to maximize safety.

- We adopt the latest national safety standards 'GB20055-2006 Open Mill Safety Standards’, which are generally the same as European CE Standards. The braking length of the roller is 1/6 rotation, maximizing safety.

- Electronic control cabinet is placed on the base which provides convenience for adjustment and installation. Once connected with a dynamic power, cooling water and lubrication oil for reducer, the rubber mixing mill can operate without issue.

- We provide custom services for clients.

Our advantage

- Shun Cheong fully considers the end users during each process of the design, manufacturing, and maintenance of the rubber mixing mill. For example, the assembly and installation of old rubber mixing mills usually takes 6 days and 7 processes, while the new one takes only 3 hours and 4 processes, which is very convenient.

- Shun Cheong manufactures about 40 pieces of different types of rubber mixing mills every year and we provide custom services to meet client demands.

Get in Touch