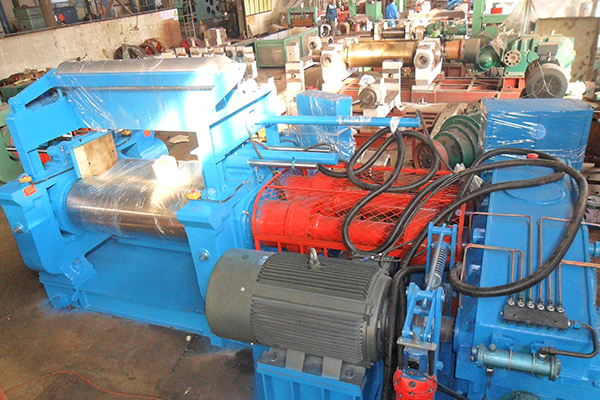

Dual Output Shaft Rubber Mixing Mill

Our dual output shaft rubber mixing mill is rubber manufacturing equipment used for uniform blending of natural and synthetic rubber with other raw materials. This rubber mixing mill can enable all raw materials to be perfectly mixed in accordance with the desired specifications.

Specifications

| Model | |

|

|

|

|

| Diameter of roll (mm) | 400 | 450 | 560/510 | 550 | 660 |

| Length of roll (mm) | 1000 | 1200 | 1530 | 1500 | 2130 |

| Front roll surface Speed (m/min) | 18.65 | 24.26 | 27.72 | 27.94 | 28.6 |

| Friction ratio | 1:1.27 | 1:1.27 | 1:1.2 | 1:1.22 | 1:1.24 |

| Max. nip (mm) | 10 | 15 | 15 | 15 | 15 |

| Capacity per batch (kg) | 18-35 | 25-50 | 35~50 | 50~60 | 165 |

| Motor power (kW) | 37 | 55 | 90 | 110 | 245 |

Features

- This dual output shaft rubber mixing mill can be equipped with hydraulic or mechanical system to automatically and continuously mix the rubber materials, thus greatly reducing labor intensity and saving mixing time;

- The planetary speed reducer is configured in the rubber mixing mill, delivering low noise level, high work efficiency and good transfer effect;

- Emergency stop button is configured to ensure the safety of both operator and equipment;

- Each of rubber mixing mill we provide is tested and inspected after 3 to 7 hours of continuous full-load operation, this aims at guaranteeing premium quality and low noise level as well as allowing user to start rubber mixing operation directly after installation;

Get in Touch