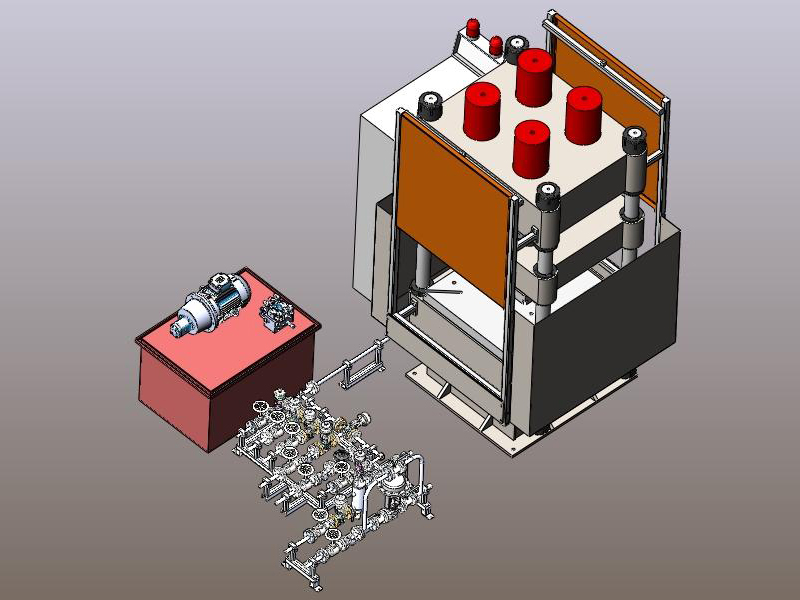

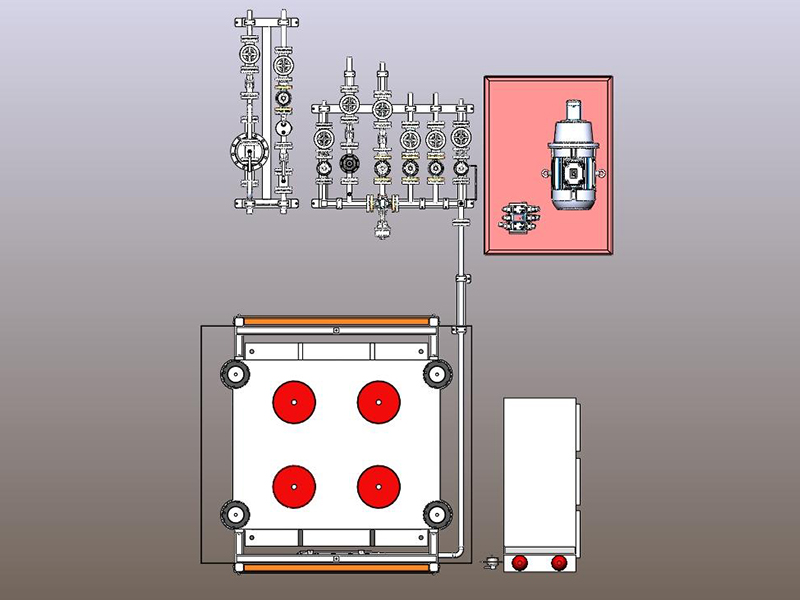

Air Spring Rubber Vulcanizing Press

Parameters

| Model | XLB-Q1000×1000/2.50MN |

| Rated clamping force (MN) | 2.5 |

| Total working pressure (T) | 250 |

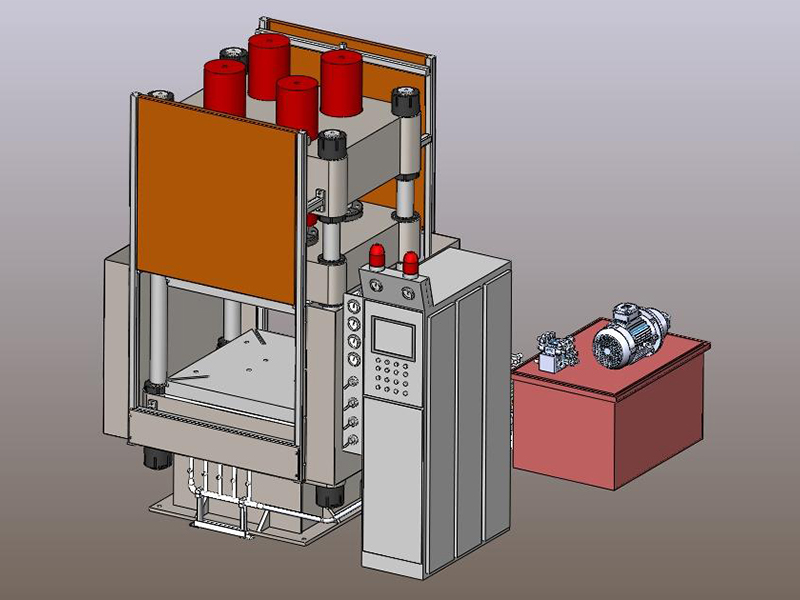

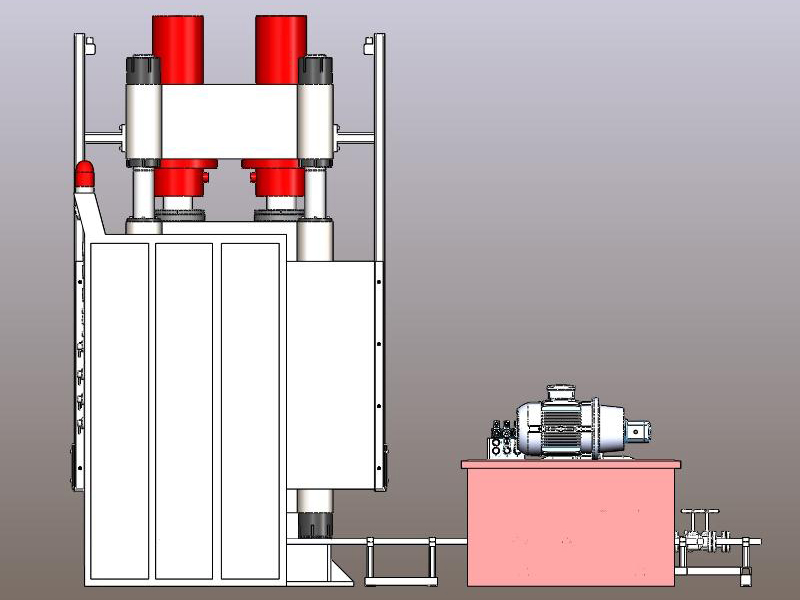

| Structure type | Column structure |

| Heating plate size (mm) | 1000x1000x88 (with T-slots for mold fixation) |

| Number of working layers | 1 |

| Clamping speed (mm/s) | ≥15 |

| Mold opening speed (mm/s) | ≥20 |

| Heating plate medium | Saturated steam (pressure: 1.6MPa) |

| Mold cavity medium | Nitrogen (Pressure: 3.0 MPa) |

| Mold cavity area (cm²) | 3000 |

| Applicable mold thickness range (mm) | 250-330 |

| Hydraulic system pressure (MPa) | 20 |

| Number of main hydraulic cylinders | 4 |

| Height of lower plate top surface from ground (mm) | 800 |

Equipment structure and features

- Both upper and lower heating plates are equipped with single-sided T-slots. T-slot layout: X-type structure, size M20.

-

Upper and lower frames are fabricated from Q235-B steel plates. To ensure accuracy, the press adopts features including automatic cutting for material preparation, welding grooves machined by planer, CO2 gas-shielded welding with alloy welding wire. Welding stress is fully relieved to prevent deformation during long-term operation, ensuring structural stability and product quality.

- Heating plates are manufactured from double-fixed-length rolled Q235 steel plates, with a surface roughness of Ra 1.6. Each heating plate is designed with one independent heating zone. Internal steam channels are optimally arranged with a spacing of 70-90mm. Manual ball valves are installed at both ends of each metal hose to facilitate replacement and reduce steam leakage during maintenance.

- A 20mm thick thermal insulation layer is installed on the top of the upper heating plate and the bottom of the lower heating plate.

Insulation material: asbestos-free resin insulation board

Pressure resistance: ≥400kg/cm²

Thermal conductivity: 0.33W/m·K

Temperature resistance: 220-250℃

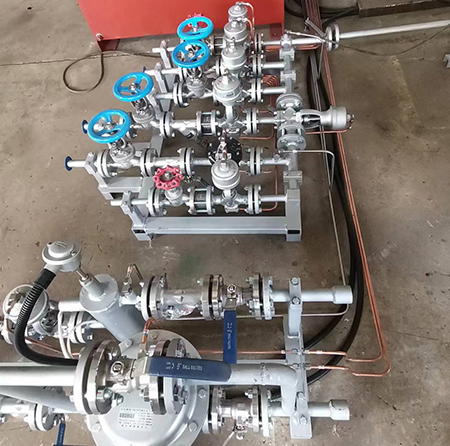

This design ensures effective heat insulation, reduced heat transfer losses, long-term resistance to local compression deformation and a service life of more than 8 years under normal operating conditions. - The hydraulic system is designed according to process requirements and motion sequences. Equipped with safety relief valves and multi-level pressure monitoring, the system ensures operating pressure within the maximum allowable limit. Cartridge valves or manifold-mounted valves are used for easy maintenance and reliable sealing performance.

- Electrical control system features a PLC+touch screen control system, with bilingual operation interface available in Chinese and English. The touch screen displays and records: Vulcanization pressure, heating plate temperature, vulcanization temperature-pressure curves, historical curves, temperature and pressure alarm information, vulcanization time, exhaust time and exhaust cycles. This configuration enables intuitive operation, precise control, and full process traceability.

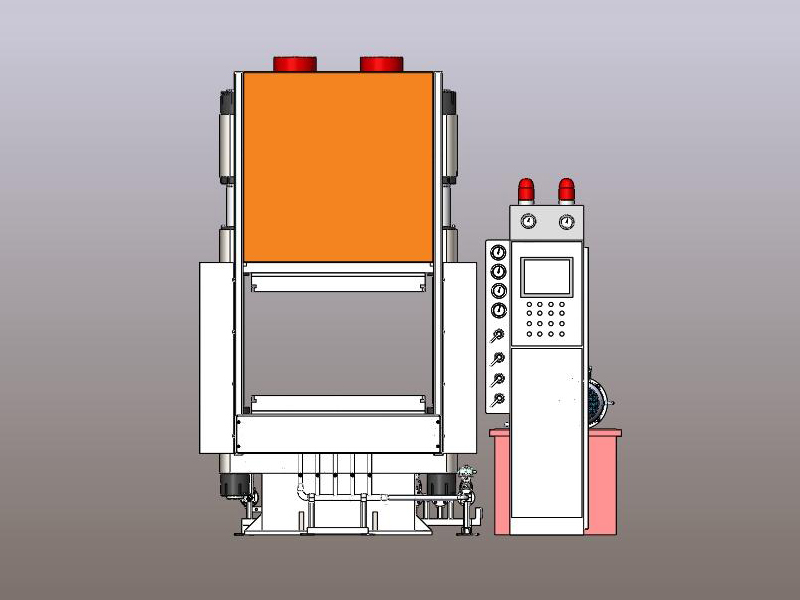

Machine appearance

Get in Touch