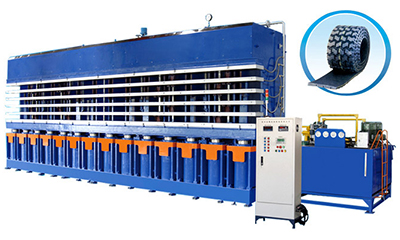

Retread Rubber Tire Tread Vulcanizing Press

Applications

The retread rubber tire tread vulcanizing press is designed to retread tires for the repair and recycling of rubber tire products.

Features

- High Tread Density

The hot plate applies a consistent pressure of 4.5Mpa per unit area, ensuring the tire tread is dense and durable throughout the retreading process - Fully Automatic Control

With PLC control and a touchscreen interface, the system automates air release and pressure adjustments for precise and efficient vulcanization Convenient Operation

The hydraulic design simplifies mold handling with an easy push-pull system, making loading and unloading quick and reducing operator effort.

Product parameters

| Type | |

| Nominal clamp force (Tons) | 650 |

| Hot plate dimension (mm) | 3600X400X70 |

| Spacing (mm) | 250 |

| No. of layer | 5 |

| Plunger stroke (mm) | 1000 |

| Open/Close mold speed (mm/s) | ≥15 |

| Cylinder diameter (mm) | 260 |

| No. of cylinder | 6 |

| Motor power (KW) | 15+5.5 |

| Type | |

| Total Pressure (Tons) | 1000 |

| Plate Size (mm) | 5000x400x700 |

| Daylight (mm) | 150 |

| Layer NO. | 3 |

| Piston Stroke (mm) | 450 |

| Open/Close Mould Speed (mm/s) | ≥15 |

| Cylinder Diameter (mm) | 285 |

| Cylinder NO. | 8 |

| Motor Power (KW) | 11+5.5 |

| Type | |

| Total Pressure (Tons) | 1668 |

| Plate Size (mm) | 5200x700x800 |

| Daylight (mm) | 150 |

| Layer NO. | 3 |

| Piston Stroke (mm) | 450 |

| Open/Close Mould Speed (mm/s) | ≥15 |

| Cylinder Diameter (mm) | 500 |

| Cylinder NO. | 5 |

| Motor Power (KW) | 13+5.5 |

How do I figure out which tire tread vulcanizing press model is the best fit for my production?

How do I figure out which tire tread vulcanizing press model is the best fit for my production?

To help you select the right tire tread vulcanizing press, we mainly pay attention to the size of the tread you plan to manufacture. If you can share the width and length of your products, we’ll recommend a model that matches those dimensions and supports consistent production.

What level of automation can I expect from the tire tread vulcanizing press you offer?

What level of automation can I expect from the tire tread vulcanizing press you offer?

Our tire tread vulcanizing presses are built for fully automatic operations. Once you start the vulcanizing process, the vulcanizing press handles everything, from pressure adjustment and temperature control to vulcanization itself and automatic mold opening. For higher productivity and less manual handling, it can also be equipped with optional features like robotic arms for automatic loading and unloading.

Get in Touch